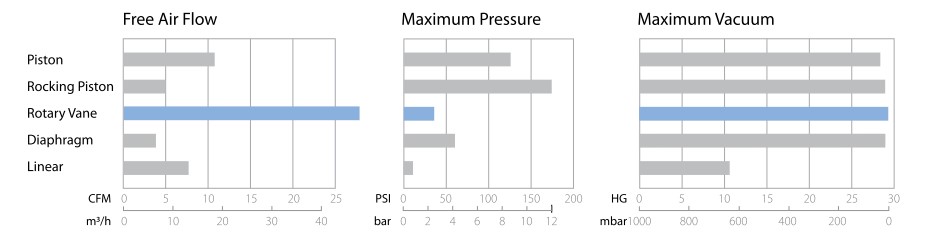

Why use a Rotary Vane Compressors and Vacuum Pumps?

Rotary Vane vacuum pumps and compressors have certain significant advantages. In addition to providing smooth,pulse-free air flow without receiver tanks, they are compact (or equivalently offer high flow capacities for a given size), are simple and economical to install and operate, have low starting and running torque requirements, produce minimal noise or vibrations, are capable of long, service-free life, and are easily serviced.

If these features are what you need in your pneumatic application, a Gast Rotary Vane model can provide you the right solution.

Pumping action is pro duced by a series of sliding, flat vanes as they rotate in a cylindrical hous – ing. As the diagram shows, an eccentrically mounted rotor turns and the individual vanes slide in and out of their slots by centrifugal and pressure-loading forces. This creates a series of air compartments of unequal volume against the wall of the housing. These compartments get larger during the suction part of the cycle, creating vacuum at the intake port and smaller during the discharge portion of the cycle, creating pressure at the exhaust port. The vacuum and pressure flows are free of pulsation because the inlet and exhaust ports do not have valves, and the air is moved continuously rather than intermittently.

Gast Rotary Vane and Vacuum Pumps Performance*

Rotary Vane Performance Overview

| MODEL/ SERIES |

POWER RATING | FREE AIR FLOW | MAXIMUM PRESSURE |

MAXIMUM VACUUM |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 60 Hz | CFM | m³/h | ||||||||||

| hp | kW | 50 Hz | 60 Hz | 50 Hz | 60 Hz | psi | bar | inHg | mbar | Page No. | ||

| Motor Mounted | ||||||||||||

| 1531 | ¹/₁₀ | 1.25 | 1.5 | 2,5 | 15 | 1,0 | 20 | 335 | 7 | |||

| 532 | ¹/₁₅ | 0,05 | .29 | .6 | 0,49 | 1,0 | 15 | 1,0 | 20 | 335 | 8 | |

| 1032 | ¹/₁₅ | 0,05 | .92 | 1.1 | 1,56 | 1,9 | 10 | 0,7 | 20 | 335 | 8 | |

| 1532 | ¹/₁₀ | 0,07 | 1.3 | 1.5 | 2,2 | 2,5 | 10 | 0,7 | 20 | 335 | 8 | |

| 2032 | ¹/₈ | 0,09 | 2.0 | 2.4 | 3,4 | 4,1 | 10 | 0,7 | 26 | 133 | 10 | |

| 3032 | ¹/₆ | 0,12 | 2.4 | 2.6 | 4,1 | 4,4 | 10 | 0,7 | 26.5 | 116 | 10 | |

| 211 | ¹/₆ | 0,12 | 1.1 | 1.3 | 1,9 | 2,2 | 20 | 1,4 | 20 | 335 | 12 | |

| 0323-1423 (6 models) | ¹/₄ -1 | 0,19 - 0,56 | 2.7 - 11.5 | 3.2 - 13 | 4,6 - 19,5 | 5,4 - 22 | 10 | 0,7 | 26.5 | 116 | 14 - 17 | |

| AT Series | ¹/₄ | 0,19 | 3.8 - 4.8 | - | - | 6,5 - 8,2 | 5 | 0,4 | 24 | 150 | 18 | |

| 2070 | 2 | 1,5 | 16 | 20 | 27 | 34 | - | - | 25 | 167 | 20 | |

| Separate Drive | ||||||||||||

| 533 | ¹/₁₅ | 0,05 | .5 | .6 | 0,85 | 1,0 | 15 | 1,0 | 20 | 335 | 22 | |

| 1033 | ¹/₁₀ | 0,07 | .9 | 1.1 | 1,53 | 1,9 | 15 | 1,0 | 20 | 335 | 22 | |

| 1034 | 0.18 | 0,13 | - | 1.6 | - | 2.7 | 10 | 0,7 | 20 | 335 | 23 | |

| 1534 | 0.18 | 0,13 | - | 2.2 | - | 3.7 | 10 | 0,7 | 20 | 335 | 23 | |

| 0240-0740 | ¹/₄ - ¹/₃ | 0,19 - 0,25 | 1.5 - 4.9 | 1.9 - 6.0 | 2,5 - 8,3 | 3.2 - 10 | 10 | 0,7 | 20 | 335 | 25 | |

| 465 | ¹/₄ | 0,19 | 3.4 | 4.0 | 5,8 | 6,8 | - | - | 28 | 335 | 28 | |

| 765 | ¹/₃ | 0,25 | 5.0 | 6.0 | 8,5 | 10 | - | - | 28 | 65 | 28 | |

| 1550 | ³/₄ | 0,56 | 11.5 | 14.5 | 19,5 | 24,7 | 15 | 1,0 | 20 | 65 | 29 | |

| 1065-2565 | ¹/₂ -1 ¹/₂ | 0,37 - 1,1 | 7.3 - 16.5 | 8.5 - 21 | 12 - 28 | 14,4 - 35,7 | 25 | 1,7 | 28 | 335 | 31 | |

| 2067-2567 | 1-1 ¹/₂ | 0,75 - 1,1 | 14 - 17 | 25 - 45 | 24 - 29 | 29 - 35,7 | 15 | 1,0 | 28 | 65 | 33-36 | |

| 2080-4080 | 2-5 | 1,5 - 3,7 | 20 - 37 | 40 | 34 - 63 | 42 - 76 | 15 | 1,0 | 25 | 167 | 38 | |

| 3040 | 2 | 1,5 | 31 | 47.5 | 53 | 68 | 10 | 0,7 | 20 | 335 | 41 | |

| 4565 | 3 | 2,2 | 36 | 55 | 61 | 80,1 | 15 | 1,0 | 25 | 167 | 44 | |

| 5565 | 3 | 2,2 | 45 | 55 | 76 | 93,5 | - | - | 20 | 335 | 46 | |

| 6066 | 5 | 3,7 | 45 | 55 | 76 | 93,5 | 15* | 1,0 | 25 | 167 | 47 | |

| 1290* | 10 | 7,5 | - | 112 | - | 190 | 20 | 1,4 | - | - | 49 | |

*Standard model performance. Soil sparging model capable of 20 psi.

**Soil sparging model.

Catalog Performance Specifications

The specifications listed are that of a unit at sea level with an ambient temperature of 70°F (21°C), operating with normal electrical current conditions. The figures stated in this catalog are nominal approximations for models without accessories. Intake filters and exhaust mufflers, and the accumulation of contaminants in them during operation, will decrease the flow of air as well as the achievable pressure.

The units that we list in this catalog are a small portion of what we actually make. Those listed are considered “standard units” and are normally available from stock in small quantities. Variations are produced for many customers and by passing on to us the application specifications we might find an existing unit that fits your requirement. If we don’t and the quantity is sufficient, we will design a “special unit” for the application.

Pictorial and dimensional data is subject to change without notice.

The information presented in this catalog is based on technical data and test results of nominal units. It is believed to be accurate and is offered as an aid in the selection of Gast products. It is the user’s responsibility to determine suitability of the product for intended use and the user assumes all risk and liability whatsoever in connection therewith.

Typical Applications

- Air sampling

- Breathing air supply

- Sewage aeration

- Soil sparging

- Dental surgical suction

- Dental vacuum mixers

- Medical aspiration

- Circulation therapy

- Envelope openers

- Collating inserters

- Vacuum frames

- Pond aeration

- Vacuum hold-down

- Vacuum forming

- Air bearings

- Oil atomization

- Food processing

- Laboratory vacuum

- Milking equipment

Product and Application Information

Many variables determine the life expectancy of a unit.

Among them are:

1. Ambient temperature

Gast’s units operate best within a temperature range of 32 °F (0 °C) to 100 °F (38 °C). Lower temperatures affect a unit’s ability to start and higher tem peratures affect its life. Contact the factory for authorization of unusual ambient conditions.

2. Duty level

3. Operating cycle

4. Operating speed

5. Condition of air handled

– Cleanliness

– Humidity

– Heat

– Chemical vapors present (corrosive, noncorrosive)

6. Unit maintenance

– Lubrication (if required)

– Filter maintenance

– Muffler maintenance