Why use a Rocking Piston Product?

Gast oilless Rocking Piston air compressors and vacuum pumps, available in single, twin, miniature, and tank- mounted styles, are the perfect choice for hundreds of applications. Choose from dual frequency, shaded pole, and permanent split capacitor (psc) electric motors with AC multi-voltage motors to match North American, European, and worldwide power supplies. A complete line of recommended accessories as well as 6, 12, and 24 volt DC models in brush and brushless types are also available.

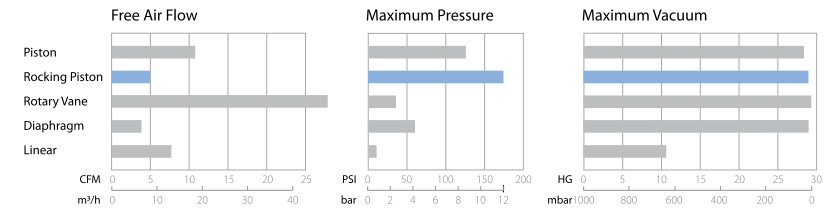

The rocking piston combines the best characteristics of piston and diaphragm air compressors into a small unit

with exceptional performance. Air flow capabilities from 3.4 LPM to 5.5 CFM (9.35 m 3 /h), pressure to 175 psi

(12.0 bar) and vacuum capabilities up to 29 inHg (31 mbar). Horsepowers range from 1/20 to 1/2 HP

(0.04 to 0.37 kW).

Rocking Piston Performance Overview

| MODEL/ SERIES |

MOTOR TYPE |

POWER RATING | FREE AIR FLOW | MAXIMUM PRESSURE |

MAXIMUM VACUUM |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 60 Hz | CFM | m³/h | ||||||||||

| hp | kW | 50 Hz | 60 Hz | 50 Hz | 60 Hz | psi | bar | inHg | mbar | |||

| 8R (DC) | - | - | 3.4 LPM | 3.4 LPM | 22.5 | 1.55 | 17 | 438 | ||||

| 20R (AC) | ¹/₃₀ | 0.025 | 12 LPM | 14.7 LPM | 12 LPM | 14.7 LPM | 35 | 2.41 | 21 | 302 | ||

| 30R (DC) | ¹/₁₀ | 0.08 | 0.61 | 1.04 | 120 | 8.28 | - | - | ||||

| 34R (DC) | ¹/₄ | 0.19 | 0.80 | 1.36 | 200 | 13.8 | - | - | ||||

| 55R | PSC | ¹/₂₀ | 0.04 | 0.16 | 0.20 | 0.27 | 0.34 | 30 | 2.1 | 24 | 200 | |

| 55R (DC) | ¹/₁₀ | 0.07 | 0.25 | 0.42 | 30 | 2.1 | 24 | 200 | ||||

| LOA | ShP | ¹/₁₆ | 0.05 | - | 0.38 | - | 0.65 | 90 | 6.2 | 25 | 167 | |

| LOA | PSC | ¹/₆ | 0.12 | 0.52 | 0.83 | 0.88 | 1.41 | 100 | 6.9 | 26 | 133 | |

| LOA (DC) | ¹/₁₀ | 0.07 | 0.62 | 1.05 | 100 | 6.9 | 27 | 99 | ||||

| LAA | ¹/₆ | 0.12 | 1.28 | 1.52 | 2.17 | 2.58 | 60 | 4.1 | 29 | 31 | ||

| SAA (STAGED) | ¹/₆ | 0.12 | - | 1.75 | - | 3.00 | - | - | 29.5 | 15 | ||

| SAA (PARALLEL) | ¹/₆ | 0.12 | - | 3.00 | - | 5.10 | - | - | 27 | 99 | ||

| SAA | ¹/₆ | 0.12 | - | 1.95 | - | 3.31 | 30 | 2.1 | - | - | ||

| ROA | ShP | ¹/₈ | 0.09 | 1.05 | 1.25 | 1.87 | 2.12 | 100 | 6.9 | 26 | 133 | |

| ROA | PSC | ¹/₄ | 0.19 | 1.50 | 1.60 | 2.55 | 2.72 | 100 | 6.9 | 27 | 99 | |

| ROA (DC) | ¹/₈ | 0.09 | 1.50 | 2.55 | - | - | 26 | 133 | ||||

| RAA | ¹/₄ | 0.19 | 2.5 | 2.7 | 4.25 | 4.59 | 100 | 6.9 | 27.5 | 82 | ||

| 71R (SINGLE CYL) | ¹/₃ | 0.25 | 2.4 | 2.0 | 4.08 | 3.40 | 100 | 6.9 | - | - | ||

| 71R (TWIN CYL) | ¹/₃ - ³/₄ | 0.25 - 0.56 | 3.25 - 4.5 | 4.0 - 4.5 | 5.52 - 7.65 | 6.80 - 7.65 | 15 - 100 | 1.04 - 7.0 | 28 | 65 | ||

| 71R (TWIN CYL HIGH PRESSURE) | ¹/₃ - ¹/₂ | 0.25 - 0.37 | 1.7 | 1.9 | 2.89 | 3.23 | 175 | 12.1 | - | - | ||

| 72R (SINGLE CYL | ¹/₃ | 0.25 | 2.0 - 2.5 | 2.5 | 3.4 - 4.25 | 4.25 | 100 | 7.0 | 28 | 65 | ||

| 72R (TWIN CYL) | ¹/₃ - ³/₄ | 0.25 - 0.56 | 2.5 - 5.5 | 2.5 - 5.5 | 4.25 - 9.35 | 4.25 - 9.35 | 25 - 100 | 1.73 - 7.0 | 29 | 31 | ||

| 74R | ¹/₄ | 0.19 | 1.30 | 1.50 | 2.21 | 2.55 | 100 | 7.0 | - | - | ||

| 75R (SINGLE CYL) | ¹/₄ | 0.25 | 1.9 | 1.9 | 3.23 | 3.23 | - | - | 27 | 99 | ||

| 75R (TWIN CYL) | ¹/₃ | 0.25 | 4.5 | 5.1 | 7.65 | 8.67 | 40 | 2.8 | 27 | 99 | ||

| 81R | ¹/₃ | 0.25 | 3.0 | 3.7 | 5.1 | 6.3 | 100 | 7.0 | - | - | ||

| 82R | ¹/₃ | 0.25 | 4.4 | 4.9 | 7.1 | 7.6 | 100 | 7.0 | - | - | ||

| 82R (BLDC) | ¹/₃ | 0.25 | 3.8 | 6.5 | 30 | 2.1 | 26 | 133 | ||||

PSC - Permanent Split Capacitor

ShP - Shaded Pole motor

Catalog Performance Specifications

The specifications listed are that of a unit at sea level with an ambient temperature of 70°F (21°C), operating with normal electrical current conditions. The figures stated in this catalog are nominal approximations for models without accessories. Intake filters and exhaust mufflers, and the accumulation of contaminants in them during operation, will decrease the flow of air as well as the achievable pressure.

The units that we list in this catalog are a small portion of what we actually make. Those listed are considered “standard units” and are normally available from stock in small quantities. Variations are produced for many customers and by passing on to us the application specifications we might find an existing unit that fits your requirement. If we don’t and the quantity is sufficient, we will design a “special unit” for the application.

Pictorial and dimensional data is subject to change without notice.

The information presented in this catalog is based on technical data and test results of nominal units. It is believed to be accurate and is offered as an aid in the selection of Gast products. It is the user’s responsibility to determine suitability of the product for intended use and the user assumes all risk and liability whatsoever in connection therewith.

Typical Applications

- Oxygen concentrators

- Eye surgery equipment

- Ventilation equipment

- Surgical aspiration equipment

- Dental vacuum ovens

- Dental compressors

- Portable dental equipment

- Lab test equipment

- Body fluid analysis

- Vacuum filtering

- Vacuum centrifuge

- Vacuum food sealer

- Tire inflation equipment

- Automotive suspensions

- Auto detailing equipment

- Refrigerants reclamation

- Dry sprinkler system

- Beverage dispensing

- Cable pressurization

- Vacuum frames

- Core drilling

- Paper counting machines

- Vacuum mixing

- Handicapped accessible doors

- Diving air