Air Motors / Gear Motors

Air Motors / Gear Motors are both important technologies that play important roles in a wide range of industrial applications. Air motors use compressed air to generate mechanical energy, while gear motors use gears to reduce speed and increase torque.

Air Motors / Gear Motors can be combined to create air-powered gear motors, which are used in many industrial applications where a high level of precision and control is required. Air-powered gear motors are often used in automated assembly lines, machine tools, and other industrial applications where precise control over the speed and torque of the motor is critical.

The choice between Air Motors / Gear Motors will depend on the specific needs of the application, including factors such as speed, torque, power, and environmental conditions. Air Motors / Gear Motors are commonly used in industrial applications where electric motors may not be practical or safe, such as in explosive environments or in wet or dirty environments. Air Motors / Gear Motors are also preferred in some situations because they are lightweight, easy to maintain, and can be designed to provide high torque at low speeds.

Why use a Gast Air Motor?

You can vary air motor speed between 300 and 10,000 rpm

(depending on model selection) with a simple valve put in between

the air source and air motor.

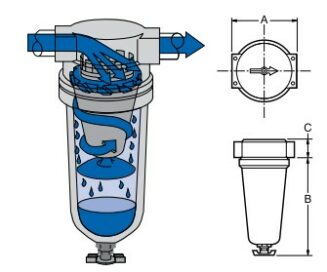

To ensure long life, Gast offers accessories designed to extend unit life including air filters that remove water and particles down to 5 microns, and air line lubricators that supply a constant flow of lubrication automatically*. We can supply a pressure regulator that provides precise control of power and operating speed. Options like

these help you get smooth performance with minimum maintenance.

*Non-lubricated series does not require a lubricator

How to Select an Air Motor ?

Air motors differ in many ways from other power sources. These unique operating characteristics must be considered when selecting an air motor for a particular job. It is easy to change horsepower and speed of an air motor by throttling the air inlet. Therefore, the best rule of thumb for selecting an air motor is to choose one that will provide the horsepower and torque needed using only two-thirds (²/₃) of the line pressure available. The full air line pressure will then be available for overloads and starting.

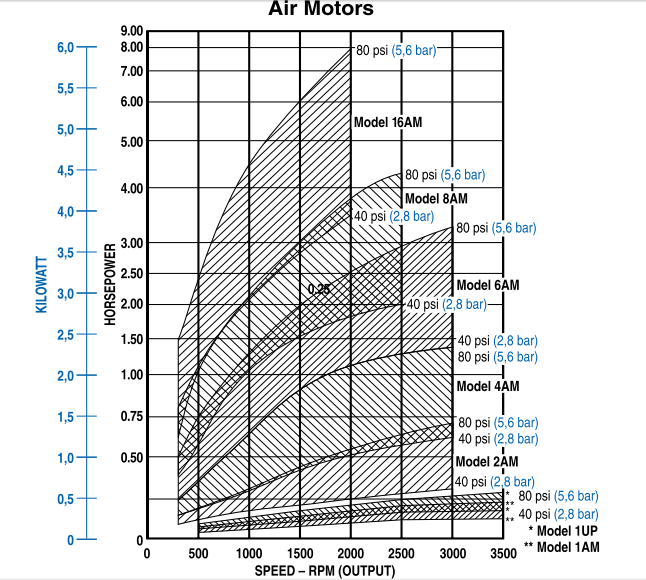

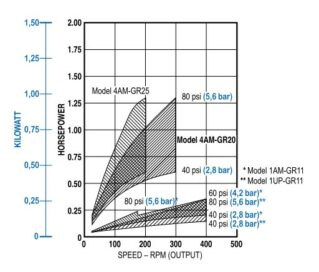

Output Power vs. Speed

The output power of an air motor is relative to speed and to air line pressure

Torque vs. Speed

1. An air motor slows down when load increases… at the same time its torque increases to a point where it matches the load. It will continue to provide increased torque all the way to the stalled condition, and it can maintain the stalled condition without any harm to the motor.

2. As the load is reduced, an air motor will increase speed and the torque will decrease to match the reduced load.

3. When the load on an air motor is either increased or decreased, speed can be controlled by increasing or decreasing air pressure.

4. Starting torque of an air motor is lower than running torque. While this provides smooth, low-shock starting, it is necessary to have additional air line pressure for starting under heavy loads.

Air Consumption vs. Speed

Air consumption increases as speed and air pressure is increased.

Air Motor/Gear Motor Performance Overview

Whatever your rotary air motor power requirements, chances are we have what you’re looking for.

Stainless Steel and Standard Air Motors Specifications

| MODEL | OPERATING DATA | MAXIMUM TORQUE | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| MAX SPEED |

OUTPUT POWER |

TORQUE | MAX. AIR CONSUMPTION |

MAX SPEED |

||||||

| rpm | HP | kW | lb. in. | Nm | cfm | m3/h | rpm | lb. in. | Nm | |

| STAINLESS STEEL AIR MOTORS | ||||||||||

| 1AM | 10,000 | 0.45 | 0,33 | 2.75 | 0,31 | 20.5 | 35,1 | 650 | 5.6 | 0,65 |

| 4AM | 3,000 | 1.70 | 1,30 | 36.00 | 4,1 | 78 | 132,5 | 300 | 56.00 | 6,3 |

| 6AM | 3,000 | 4.00 | 3,00 | 84.00 | 10,00 | 128 | 228 | 300 | 115.00 | 13,00 |

| STANDARD AIR MOTORS | ||||||||||

| 1AM (A) | 10,000 | 0.45 | 0,33 | 2.75 | 0,31 | 20.5 | 35,1 | 650 | 5.6 | 0,65 |

| 1UP (B) | 6,000 | 0.45 | 0,33 | 5.25 | 0,58 | 27 | 47 | 500 | 6.00 | 0,68 |

| 2AM (A) | 3,000 | 0.93 | 0,68 | 19.50 | 2,20 | 30 | 49,5 | 350 | 26.10 | 3,05 |

| 4AM (A) | 3,000 | 1.70 | 1,30 | 36.00 | 4,1 | 78 | 132,5 | 300 | 56.00 | 6,3 |

| 6AM (A) | 3,000 | 4.00 | 3,00 | 84.00 | 10,00 | 128 | 228 | 300 | 115.00 | 13,00 |

| 8AM (A) | 2,500 | 5.25 | 3,90 | 132.00 | 14,40 | 175 | 293 | 300 | 185.00 | 31,00 |

| 16AM (A) | 2,000 | 9.50 | 7,10 | 290.00 | 34,00 | 275 | 475 | 300 | 372.00 | 43,0 |

Gear Motors Specifications

| MODEL | OPERATING DATA | MAXIMUM TORQUE | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GEAR RATIO |

MAX SPEED rmp |

LINE PRES. |

OUTPUT POWER |

TORQUE | MAX. AIR CONSUMPTION |

MAX SPEED |

||||||

| rpm | HP | kW | lb. in. | Nm | cfm | m3/h | rpm | lb. in. | Nm | |||

| Gear MotorS | ||||||||||||

| 1AM-NRV | 15:1 | 350 | A | 0.34 | 0,26 | 62 | 7,1 | 21.0 | 36 | 30 | 72 | 8,1 |

| 1UP-NRV | 15:1 | 400 | C | 0.32 | 0,23 | 49 | 5,5 | 2 | 36 | 30 | 71 | 8,0 |

| 2AM-43A | 20:1 | 150 | C | 0.26 | 0,39 | 110 | 12,4 | 18 | 30,6 | 60 | 145 | 16,4 |

| 2AM-43A | 20:1 | 150 | A | 0.58 | 0,43 | 240 | 27,1 | 42 | 71,4 | 60 | 270 | 30,5 |

| 4AM-RV | 10:1 | 300 | B | 1.26 | 0,94 | 274 | 31,0 | 57.5 | 98 | 30 | 425 | 48,0 |

| 4AM-RV | 15:1 | 200 | B | 1.25 | 0,90 | 400 | 45,2 | 60.0 | 102 | 20 | 640 | 72,0 |

| 4AM-70C | 20:1 | 150 | A | 1.17 | 0,87 | 487 | 55,0 | 71.0 | 120 | 15 | 740 | 83,6 |

| 4AM-70C | 40:1 | 75 | A | 0.95 | 0,71 | 800 | 90,4 | 71.0 | 120 | 7 | 1255 | 141,8 |

| 4AM-70C | 60:1 | 50 | A | 0.82 | 0,61 | 1040 | 117,5 | 71.0 | 120 | 5 | 1640 | 185,3 |

| 6AM-22A | 10:1 | 300 | A | 3.40 | 2,54 | 720 | 81,4 | 130.0 | 221 | 30 | 950 | 107,4 |

| 6AM-22A | 20:1 | 150 | A | 2.65 | 1,98 | 1100 | 124,3 | 130.0 | 221 | 15 | 1550 | 175,6 |

| 6AM-22A | 40:1 | 75 | A | 2.10 | 1,57 | 1725 | 194,9 | 135.0 | 230 | 8 | 2500 | 282,5 |

| 8AM-32A | 20:1 | 125 | A | 3.70 | 2,76 | 1850 | 209,1 | 177.0 | 301 | 15 | 2550 | 288,2 |

| 16AM-13 | 20:1 | 100 | A | 6.50 | 4,85 | 4175 | 471,8 | 275.0 | 468 | 15 | 5175 | 584,8 |

A – 100 psig and 7,0 bar line pressure for imperial and metric data, respectively.

B – 80 psig and 5,5 bar line pressure for imperial and metric data, respectively.

C – 60 psig and 4,1 bar line pressure for imperial and metric data, respectively.

Catalog Performance Specifications

The specifications listed are that of a unit at sea level with an ambient temperature of 70 °F (21 °C), operating with normal electrical current conditions. The figures stated in this catalog are nominal approximations for models without accessories. Intake filters and exhaust mufflers, and the accumulation of contaminants in them during operation, will decrease the flow of air as well as the achievable pressure.

The units that we list in this catalog are a small portion of what we actually make. Those listed are considered “standard units” and are normally available from stock in small quantities. Variations are produced for many customers and by providing to us the application specifications we might find an existing unit that fits your requirement. If we don’t and the quantity is sufficient, we will design a “special unit” for the application.

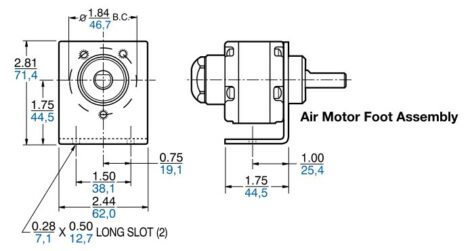

Pictorial and dimensional data is subject to change without notice.

The information presented in this catalog is based on technical data and test results of nominal units. It is believed to be accurate and is offered as an aid in the selection of Gast products. It is the user’s responsibility to determine suitability of the product for intended use and the user assumes all risk and liability whatsoever in connection therewith.

The chart below shows general performance ranges of our lubricated Air Motors.

See if we have the right offering for your application.

Use of Air Motors in Hazardous Atmospheres

Most of the Gast Air Motors and some of the Gast Gear Motors in this catalog meet the requirements of the EC directive 94/9EC (ATEX 100a). They may be used in zones 1 and 2 where explosive atmospheres of gas or dust are likely to occur. These are marked with εx II 2 G D c T4 in the catalogue and on the product. This indicates the air motor is Group II, Category 2, Gas and Dust Atmospheres, and a maximum surface temperature of 275 °F/135 °C. Check that the product driven by the air motor meets ATEX directive.

There are several points regarding the safety of air motors. Our air motors are not a source of electric sparks. However, it is possible that an article which is not part of the air motor (e.g., wrenches, hammers, etc.) could create a spark by sharply impacting a cast iron or aluminum case or the steel shaft of the air motor. [Note that electric motor enclosures for both class I and II hazardous locations can be made of “…iron, steel, copper, bronze, or aluminum…” (UL 674, Electric Motors and Generators – Hazardous Locations, June 23, 1989; paragraph 4.2, page 6)].

Gast Air Motors are designed to be operated by compressed air, the expansion of which creates a cooling effect. As a result, the outside surface temperature of the air motor will not reach ignition temperature and a maximum surface temperature of 275 °F/135 °C. Operation of the air motor with compressed air purges a flammable mixture from the inside of the air motor.

To prevent static electricity from being an ignition source electrically ground the metal air motor.

We do not guarantee the safety of any application, but to ensure the safe operation of an air motor in your application, always follow the product operation manual, follow ATEX 100a when operating in a hazardous atmosphere and consult with a qualified engineer.

Performance, Features and Typical Applications

Performance

- Up to 9.5 HP (7,1 kW)

- Variable speeds to 10,000 rpm Gear

- motor maximum torque to 5200 lb. in. (587 Nm)

Features

- Variable speed

- Non-electrical sparking

- Cool running

- Compact and portable

- Operate in all positions

- Mounting flexibility

Typical Applications

- Typical

- Applications

- Mixing

- equipment

- Conveyor drives

- Pump drives

- Food packaging

- Pharmaceutical

- packaging

- Hoists and

- winches

- Hose reels

- Fiberglass

- choppers

- Tension devices

- Turntables

- Tire/wheel

- balancers

Air Motors

Air Motors Other Spec.

Stainless Steel Air Motors

- Sanitary design

- 304 stainless steel housing, rotor, and output shaft

- Hub, face, or flange mounting

- Any plane operation

- Fully sealed

Stainless Steel Air Motors Other Spec.

Metric Models

Metric Models Other Spec.

Non-lubricated Air Motors

Like our traditional lubricated air motors, the NL series will provide thousands of hours of service-free life. Vanes are just as easy and inexpensive to replace.

Gast’s non-lubricated air motors are designed so that com-pressor carry-over will not gum up the vanes. In fact, whileno lubrication whatsoever is required to operate the motors,small amounts of oil and water will actually improve the performance.

Because the body, rotor, and end plates are specially treated,

these air motors can tolerate unfavorable moisture-laden

conditions.

If you are using several quarts of oil throughout the year, you’ll eliminate that expense with non-lubricated air motors.

Gast’s non-lubricated Air Motors provide the advantages and benefits of traditional lubricated air motors which include:

- Variable speed

- Non-electrical sparking

- Cool running

- Minimal maintenance

- No-shock starts

- Any plane operation

Non-lubricated Air Motors Other Spec.

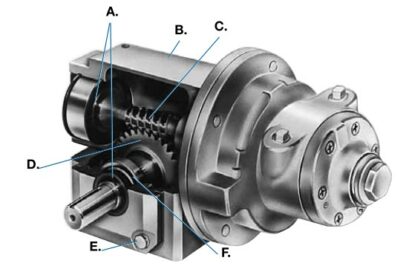

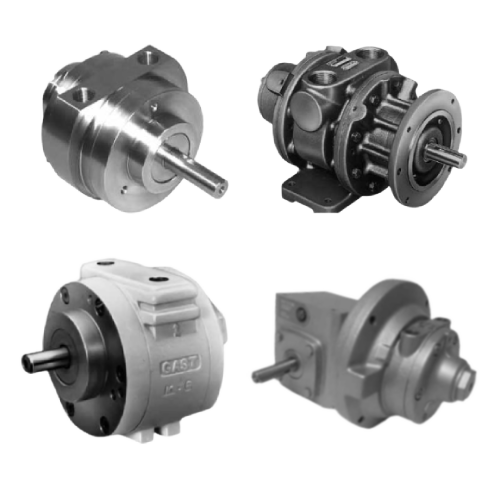

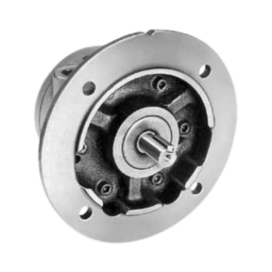

Air-Powered Gear Motors

Fine close-grain cast iron; crankcase sealed; duplex-milled for parallelism of mounting surfaces.

8620 alloy steel thread rolled to give uninterrupted grain pattern; carburized and hardened after rolling; high-burnish contact surface from rolling reduces friction coefficient for less heat generation, lower power losses. In large sizes, worms are cut, hardened, and ground to a good micro-finish, providing the ultimate in efficiency and torque capacity.

Forged bronze; geometry and high helix angle give maximum beam strength, high efficiency.

Get the right gear motor with all the right options

If you compare Gast Air-Powered Gear Motors with any electric-powered gear motor, there’s really no comparison. Here’s why :

Size for size, weight for weight, you can’t beat a Gast Gear Motor. A typical rotary vane air motor – the type used in gear motors – developing 2 ¹/₂ HP (1,9 kW) at 1800 rpm and 90 psi (6,2 bar), weighs just 17 pounds (7.7 kg). A comparable electric motor may be two or three times heavier.

You can’t get more precise turning power than with a Gast Gear Motor. In applications where you need variable speed – like bolt tensioning equipment or rock drilling rigs – one-speed electric motors just won’t fit the bill. Precise lifting, lowering, or turning is simple with Gast Gear Motors.

More than most standard electric-powered gear reducers can provide. Gast Gear Motors give you infinitely variable turning power from 73 to 5200 lb. in. (8 to 587 Nm) of torque. And Gast Gear Motors are instantly reversible through easy valving in the air line.

That makes it easier for our product to work in your product.

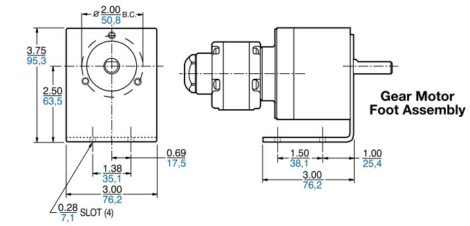

Our Gear Motors are available in four mounting configurations.

Unlike electric-powered gear motors, there’s no chance of burnout with a Gast Gear Motor. They can be stalled indefinitely with no heat buildup. They’re non-electrical sparking too, which makes them ideal for use in potentially explosive environments

– places where you couldn’t even consider electricity.

Spur Gearmotor

Air-Powered Gear Motors Other Spec.

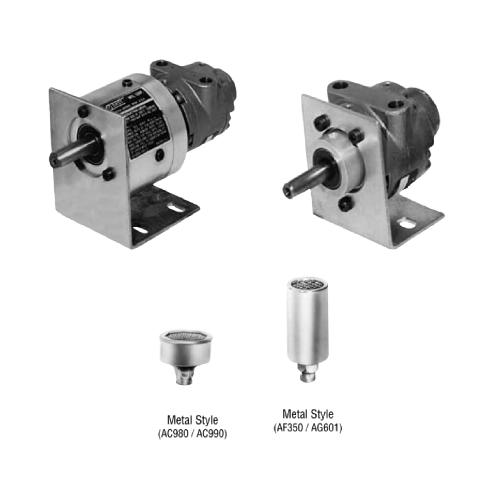

Accessories

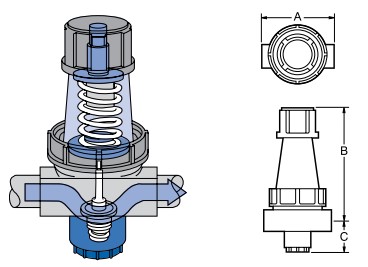

– Regulator Maximum primary pressure: 250 psi (17 bar)

– Secondary pressure range: Standard 2-125 psi (.14 to 8.6 bar)

– Temperature rating: -10 °F to 175 °F (-23 °C to 80 °C)

– Polycarbonate Bowls

200 psi at 120 °F (14 bar at 49 °C) or less

100 psi at 175 °F (7 bar at 80 °C) or less

– 1 ounce for ¹/₈ ” model

– 5 ounce for ¹/₄ ” model

– 8 ounce for ¹/₂ ” model

– 32 ounce for 1″ model

Filters • Regulators • Lubricators

FILTERS

| Gast Part Number |

Port Size |

Flow* SCFM |

Used With |

Dimensions - in.(mm) | |||

|---|---|---|---|---|---|---|---|

| A | B | C | |||||

| +AH100F | ¹/₈" NPTF | 18 | 1AM/1UP/NL22 | 1.63 (41,4) | 3.25 (82,6) | 0.38 (9,7) | |

| +AH103F | ¹/₄ " NPTF | 50 | 2AM/4AM/NL32/NL42 | 2.75 (69,9) | 5.84 (148,3) | 0.69 (17,5) | |

| +AH106F | ¹/₂ " NPTF | 117 | 6AM/8AM/NL52 | 3.91 (99,3) | 6.69 (169,9) | 0.67 (17,0) | |

| +AH109F | 1" NPTF | 365 | 16AM | 4.75 (120,7) | 10.44 (265,2) | 1.25 (31,8) | |

*SCFM = Standard cubic feet per minute at 100 psi inlet and 5 psi pressure drop.

+Metal Bowl

REGULATORS

| Gast Part Number |

Port Size |

Flow* SCFM |

Used With |

Dimensions - in.(mm) | |||

|---|---|---|---|---|---|---|---|

| A | B | C | |||||

| +AH101R | ¹/₈" NPTF | 11 | 1AM/1UP/NL22 | 1.63 (41,4) | 2.38 (60,5) | 0.38 (9,7) | |

| +AH104R | ¹/₄ " NPTF | 50 | 2AM/4AM/NL32/NL42 | 2.75 (62.0) | 4.00 (101,6) | 1.54 (39,1) | |

| +AH107R | ¹/₂ " NPTF | 130 | 6AM/8AM/NL52 | 3.50 (88,9) | 5.36 (136,1) | 1.50 (38,1) | |

| +AH110R | 1" NPTF | 360 | 16AM | 4.25 (108,0) | 5.69 (144,5) | 2.38 (60,5) | |

*SCFM = Standard cubic feet per minute at 100 psi inlet, 80 psi secondary setting and 10 psi pressure drop.

LUBRICATORS

| Gast Part Number |

Port Size |

Flow* SCFM |

Used With |

Dimensions - in.(mm) | |||

|---|---|---|---|---|---|---|---|

| A | B | C | |||||

| +AH102L | ¹/₈" NPTF | 13 | 1AM/1UP | 1.77 (45,0) | 3.37 (85,6) | 1.76 (44,7) | |

| +AH105L | ¹/₄ " NPTF | 20 | 2AM/4AM | 2.56 (65,0) | 5.75 (146,1) | 1.85 (47,0) | |

| +AH108L | ¹/₂ " NPTF | 90 | 6AM and 8AM | 3.91 (99,3) | 6.69 (169,9) | 1.88 (47,8) | |

| +AH111L | 1" NPTF | 290 | 16AM | 4.50 (114,3) | 10.24 (260,1) | 2.22 (56,4) | |

*SCFM = Standard cubic feet per minute at 100 psi inlet and 5 psi pressure drop.

+Metal Bowl

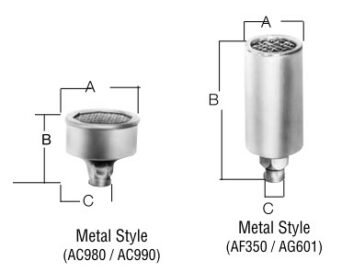

| Gast Part Number |

Used On |

Dimensions - in (mm) | ||

|---|---|---|---|---|

| A | B | C | ||

| AF350 (Metal) | 1AM/1UP/NL22 | 1.06 (27) | 2.81 (71) | 1/8" NPT |

| AC980 (Metal) | 2AM/4AM/NL32/NL42 | 1.72 (44) | 2.31 (59) | 1/4" NPT |

| AC990 (Metal) | 6AM/8AM | 2.72 (69) | 2.94 (75) | 1/2" NPT |

| AG601* (Metal) | 16AM | 3.12 (79) | 21.22 (539) | 1 1/4" NPT |

* Not included with 16AM series, but is recommended.

OIL

| Gast Part Number | Used On | |

|---|---|---|

| Food Grade Oil AS117 | Only stainless steel air motors | |

| Oil AD220 | All other Lubricated air motors | |